Man has been burning wood as a renewable, carbon-neutral fuel for thousands of years, but it’s only recently that we have given much thought to what is coming out of the chimney. As Americans, we seem to be more behind the curve in this realm more than most countries. There are some wonderful new North American products out there, but in reality, the Europeans have been at this game a long time. They have it down pretty good if you are comparing a high tech gasification boiler to a firebox submerged in water.

Here in the USA, more and more communities are concerned about airborne particulate, and with the government clamping down on woodstoves over the years, new EPA-rated stoves are burning cleaner, longer, and produce more heat with less wood. States are passing regulations requiring all new and replacement stoves to be EPA-certified and to display test results where the world can see. As a result, North American manufacturers have stepped up to the plate and re-engineered their product line, leading to a behind-the-scenes competition amongst manufacturers to produce the cleanest stoves. It is now a sense of pride to build the cleanest stove.

Some manufacturers added catalytic combustors and a new replaceable product for their dealers that needs servicing every year and replacement every few years. The better manufacturers played around with secondary combustion. By injecting air into the top of the firebox they found they could re-burn the gasses and get more heat and less smoke. Today, the best woodstoves do not rely on catalytic combustors.

All of this leads to the fact that the EPA is now taking a long hard look at wood-fired boilers, and the only boilers that will meet their new regulations are the style of gasification boilers that have been used in Europe for over thirty years!

Did you realize that in Switzerland it would be illegal to sell or install a typical North American outdoor wood boiler- the kind that has been sold and installed by tens of thousands of people? The same holds true for most of Europe. They are amazed that we would burn such an outrageous product, and are even more stunned at how popular they are here. However, that is changing rapidly as folks begin to do their homework online and see how the rest of the world does it.

3 Steps to Complete Combustion

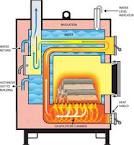

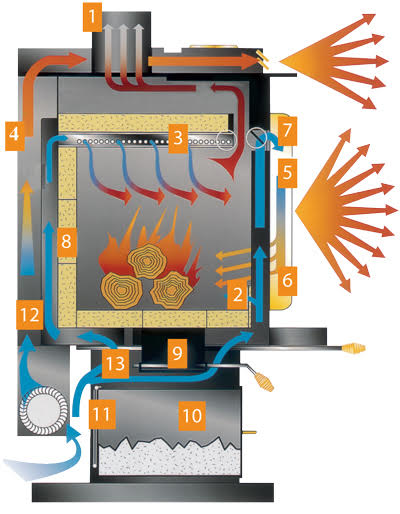

To efficiently burn solid fuels such as wood, you need complete combustion. For complete combustion you need 3 things: Fuel, air, and ignition. How you control that process determines how well combustion occurs. By moving the combustion below the firebox where the wood sits, you super heat the fuel, which vaporizes as a gas, and that gas is drawn through a funnel where re-combustion occurs at 2000 degrees. There is very little particulate that escapes the chimney; instead of smoke, there is water vapor.

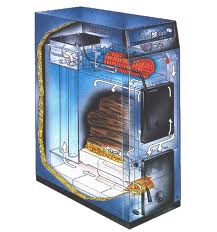

Below are various pictures of gasification boilers where the combustion chamber is below, with combustion controlled through variable speed blowers and oxygen controls. As you can see by the way the fire burns and how hot it gets, the thick refractory reflects all that intense infrared energy back, raising the combustion temperature. It’s like that of a steel blast furnace, and far higher than if it were surrounded with water and steel. The Pro Fab Elite (below) is a good example.