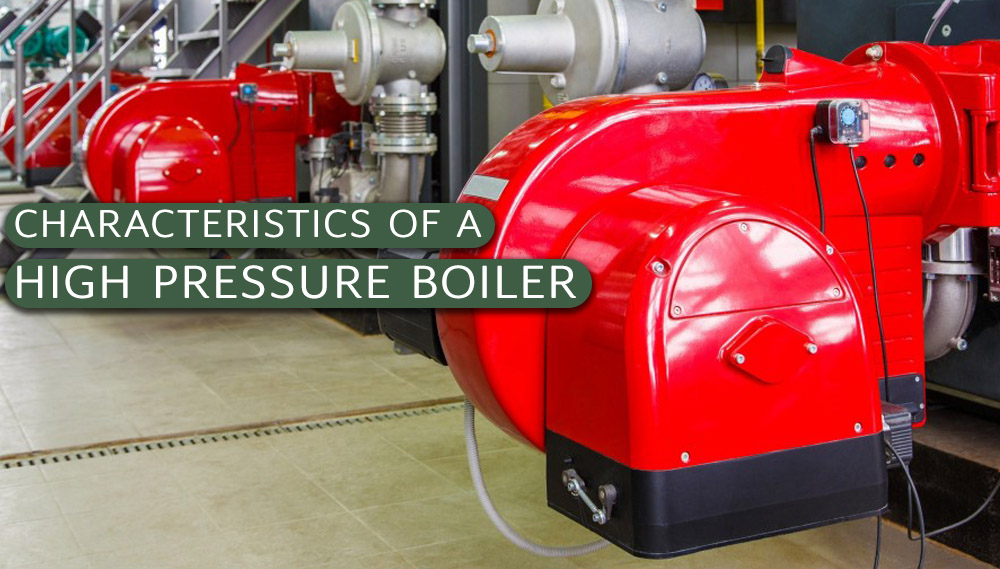

High pressure boilers differ from other methods of energy creation by fuel, emissions, and efficiency. All of these factors have an effect on the equipment’s performance and cost. Some of the characteristics of a high-pressure boiler are listed below:

Power of Steam:

Steam is formed when water expands 1600 times. Steam consists of large amounts of heat, which makes water a cost-effective and ideal raw material for creating heat and power. High pressure boilers create steam by heating water at over 15 psi and have water pressure over 160 psig.

Combustion Efficiency:

Combustion efficiency differs from stack loss, which is the heat loss by flue gases and moisture. It is the measure of how well the fuel is being burnt in combustion. High pressure boilers are extremely efficient with all of the fuel being converted to thermal energy.

Thermal Efficiency:

High pressure boilers are up to 95% thermally efficient. Thermal efficiency is the ability of a heat exchanger to transfer heat from the heating process to water or steam.

Fuel-to-Steam Efficiency:

ASME Power Test Code is used to measure fuel-to-steam efficiency. It is the ratio of BTU output and the BTU input. The input is the amount of feedstock used in combustion, while the output is the steam produced. In most cases, high pressure boilers have an 85% fuel to steam efficiency.

Stack Temperature and Losses:

Temperature loss due to the combustion of gas in a boiler is called Stack temperature. An efficient boiler uses the maximum heat generated from combustion. To avoid stack loss, the amount of air is controlled in high pressure boilers to avoid excess air. The amount of air needed is dependent on the type of fuel.

Excess Air:

15 – 20 % excess air is normally required in burners to burn efficiently. However, the amount of excess air is kept to a minimum in high-pressure boilers. Existence of excess air can be proved by the rise of flue gas temperature.

Radiation and Convection Losses:

Radiation and convection losses are dependent on the type, size, and pressure of the boiler. These losses occur due to the difference in temperature of the boiler and its surroundings. Though it is impossible to totally eliminate radiation and convection losses, insulation of pipe and boiler body help in controlling their effect.

Heating Surface:

Efficiency of a boiler depends on the heating surface a boiler has per horsepower. Generally, a boiler produces 5 to 7.5 lbm/hr of steam per square foot of heating surface.

Flue Gas Passes:

The number of passes flue gas makes before leaving the boiler is an effective way of examining efficiency. As the gas moves around the boiler, it cools down changing its volume. The more passes it makes, the efficiency of the boiler increases, thus increasing the gas velocity.

Burner:

The performance of a boiler depends greatly on the burner, controller, and boiler working as a cumulative system. Furthermore, the efficiency of the burner is important to evaluate the cost of the boiler. Burners have precise air levels that ensure complete combustion.

Written by John Hamlin